Computational Design of Actuated Deformable Characters

M. Skouras, B. Thomaszewski, S. Coros, B. Bickel, M. GrossProceedings of ACM SIGGRAPH (Anaheim, USA, July 21-25, 2013), ACM Transactions on Graphics, vol. 32, no. 4, pp. 82:1-82:10

Abstract

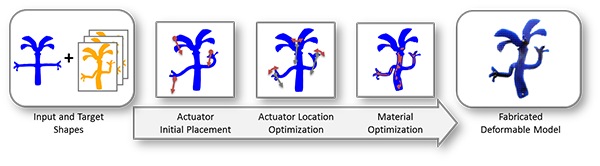

We present a method for fabrication-oriented design of actuated deformable characters that allows a user to automatically create physical replicas of digitally designed characters using rapid manufacturing technologies. Given a deformable character and a set of target poses as input, our method computes a small set of actuators along with their locations on the surface and optimizes the internal material distribution such that the resulting character exhibits the desired deformation behavior. We approach this problem with a dedicated algorithm that combines finite-element analysis, sparse regularization, and constrained optimization. We validate our pipeline on a set of two- and three-dimensional example characters and present results in simulation and physically-fabricated prototypes.Overview

Character design is a vital part of animated movie production, game development and other applications of computer graphics. Many virtual characters are rigidly articulated, others are very deformable, and most of them show properties between these two extremes ranging from humanoid virtual actors with bulging muscles, to invertebrate figures like jelly monsters and stylized background characters such as plants, buildings and other man-made objects. Digital characters are typically created solely for the virtual worlds they live in. However, many other applications such as theme park attractions, exhibitions, artistic installations or nextgeneration games require real, physical embodiments of these figures. While there is an extensive set of tools for digital character design and animation, translating animated characters to the real world is an extremely difficult task. This problem is made even more evident by the quickly growing availability of rapid manufacturing devices and services that might soon lead to a switch from mass fabrication to personalized design of characters such as action figures. Motivated by these observations, we propose a method for fabrication-oriented design of actuated deformable characters. Given a digital representation of an animated (or animatable) character as input, we seek to find a system of external actuators as well as an internal material distribution that allow us to fabricate a physical prototype whose range of deformation and movements closely approximate the input. Our solution to this problem is a dedicated algorithm that combines finite-element analysis, sparse regularization, and constrained optimization. We demonstrate our method on a set of two- and three-dimensional example characters. We present results in simulation as well as physically-fabricated prototypes with different types of actuators and materials. Our method accepts as input a mesh describing a deformable character in its neutral state as well as a set of target shapes that represent desired deformations. We then optimize for the actuation parameters (number, placement, and forces) and an internal material distribution that allow us to fabricate a physical character whose range of deformation closely approximates the target shapes. Our formulation admits arbitrary types of actuators, but we focus on three variants in this work: pin-type actuators that can apply arbitrary forces at a given location, string-type actuators that can apply forces only in certain directions, and clamp-type actuators that prescribe the positions for sets of vertices, thus emulating the process of posing characters by hand.

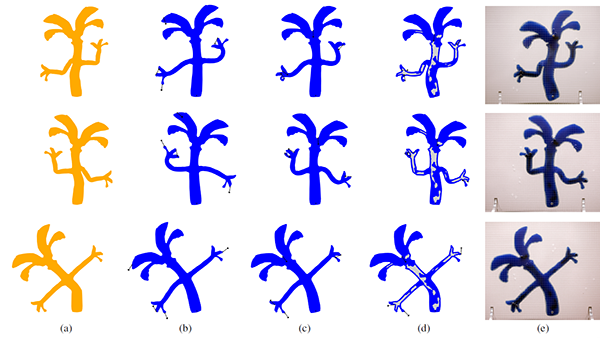

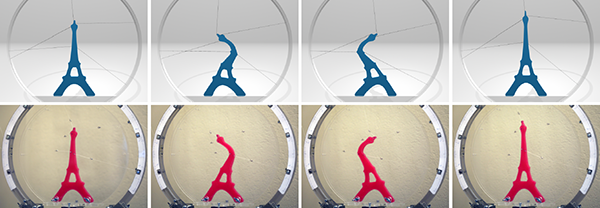

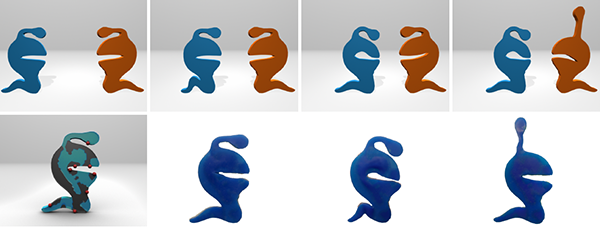

Results

We evaluated our method by designing and fabricating six characters with different types of actuators and materials. For fabrication, we used an Objet Connex350 multi-material printer with two base materials of significantly different stiffnesses. We chose VeroClear, a rigid and transparent material, and TangoBlack+, a black material with properties similar to soft rubber. Three of the characters were printed directly whereas the remaining three were fabricated using silicone injection molding with 3D-printed rigid parts. We simulated the material behavior during the design process using measured data for silicone and data provided by Objet for the 3D-printed materials.